A Beautiful Boat. A Dirty Job. A Happy Environment.

In 2019 a team led by Chief Instructor Sean Koomen from the Northwest School of Wooden Boatbuilding in Port Hadlock Washington State, came out to Australia for the Wooden Boat Festival in Hobart, and in conjunction with the Wooden Boat Centre in Franklin, built a Herreshoff Haven 12 ½.

It’s so important to have these cross hemisphere connections… so when I saw this great little story which covers all the things we at SWS feel are so important, youth involvement, environmental custodianship and female participation, then we felt we had to republish. And surely this is the worlds best looking sewage barge! Many thanks to NWSWB for sharing!

Built by students at the Northwest School of Wooden Boatbuilding

Presenting CLEAN BAY, an all electric pump out boat, providing free pump out services to recreational mariners in Port Ludlow, Wa. Not only was this boat designed to have a low carbon footprint but its functional purpose is to help save our planet by protecting a local marine environment. Every little bit helps. If that were not enough, its construction by the Northwest School of Wooden Boatbuilding gave students in the Boatbuilding and Marine Systems programs problems to solve in the real world which are present any time a new design with new technologies is taken on.

Marine Systems students, led by Marine Systems Lead Instructor Kevin Ritz, were given a preview of the future when they installed CLEAN BAY’s systems. From a Torqeedo Electric Propulsion System, lithium-ion battery banks and solar panels to an advanced impressed cathodic corrosion protection system, they are responsible for creating CLEAN BAY’s green footprint. Not only will CLEAN BAY protect the local waters from recreational boat waste discharge, it will also protect Port Ludlow from accidental fuel/oil leakage, since it carries no fossil fuels and prevent deposition of heavy metals by avoiding the more common “zincs” traditionally used for corrosion protection. “We’re teaching and deploying state-of-the-art systems and propulsion technology for which, in many cases, standards have yet to be written,” says Ritz.

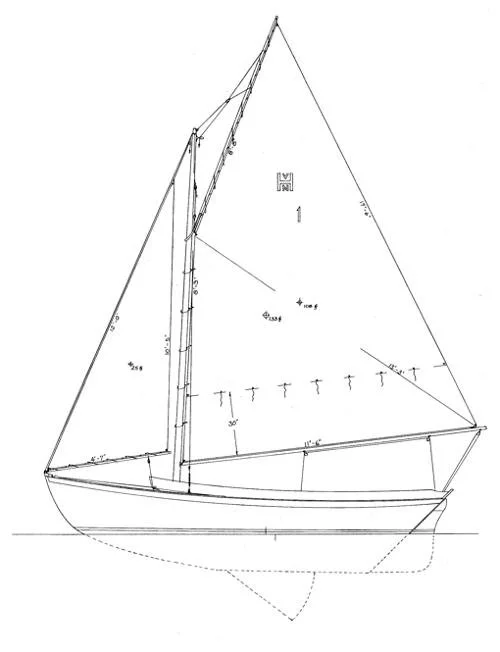

Boatbuilding students were tasked with bringing to life a new design created by local marine architect, Tim Nolan. The majority of the workboat was cold-molded construction but also included plenty of “traditional” construction techniques to challenge the students.

Staying true to the mission of the school, Boatbuilding Instructor Bruce Blatchley says, "We’re not just building boats, our main product is education. Building Clean Bay has given boatbuilding students experience with laminating, strip-planking, and cold-molded construction; vacuum infusion; foam core construction; working with CNC production; millwork; and joinery.”

The project is a joint effort between local marine businesses, private donors, and state agencies which share a common goal of promoting environmental stewardship – from its zero-emission propulsion system to its role in keeping waterways free of wastewater. It has already been recognized by the state’s Maritime Blue Initiative for modeling effective use of zero-emissions systems for workboats.

For all that the Clean Bay takes away it also gives back. The Northwest School of Wooden Boatbuilding is leasing Clean Bay to the Port Ludlow Marina who will provide free pump outs. Ritz also plan to bring future students to tour the boat and learn about its operations and construction.