Cheoy Lee Shipyards

by Charlie Salter

Arthur C Robb was a New Zealand naval architect working in London from the 1940’s. His yachts are still sailed around the world but particularly in the United States. Here in Australia Robb designs were built from the 1950’s.

SIANDRA is a Robb 35’ Lion Class built by Ron Swanson in Sydney in 1956. She won the Sydney Hobart in 1958 and 1960. Classic sailors in Melbourne know AKALA, a 37’ Robb Princess Class launched in 1963. The 38’ Robb auxiliary cutter MOKOIA, built in the UK in 1948 for transatlantic racing is now moored in the Hastings River at Port Macquarie NSW. See REIMERS & ROBB SWS Sept 2nd.

More stories about Arthur Robb yachts including his Daring one-design and the New Zealand K Class are coming in November editions of SWS.

Cheoy Lee Robb 35 MARCO POLO on Sydney Harbour

MARCO POLO

MARCO POLO (the subject of another article in this weeks SWS) is a Robb 35 recently re-floated and rescued in Sydney. She’s now in the capable hands of MacKenzie Marine, Palm Beach Sydney. See THAT SINKING FEELING SWS 28th October

MP is a Cheoy Lee Robb, built in Hong Kong in 1962. Yachts with names like CHINA DOLL, KUONG GEE, MAH JONG, MARCO POLO, MING FOO and PING PO are still sailing in Australia, Bermuda, Monterey, Lake Erie and Long Island Sound. What makes them unique is their builder. From the 1950's to the 1980's, Cheoy Lee Shipyards in Hong Kong were commissioned to build over 4,500 yachts to the designs of the world’s best naval architects like John Alden, Laurent Giles, Bill Luders, Philip Rhodes and Sparkman & Stephens. Arthur Robb’s designs were prolific amongst these boats.

Cheoy Lee yachts have legions of fans and associations around the world. They are always advertised as a Cheoy Lee Robb or a Cheoy Lee Rhodes etc. and devotees are prepared to pay a premium. So what’s going on? The simple answer is the early Cheoy Lee yachts were built completely from Burmese teak on Ipol (merbau) frames. Using old growth rainforest teak today, let alone Burmese, will test your politics and green credentials. This celebrated timber is now a very rare resource and the market is controlled by companies owned by the military junta that came out to play in Myanmar in February 2021.

THE CHEOY LEE STORY

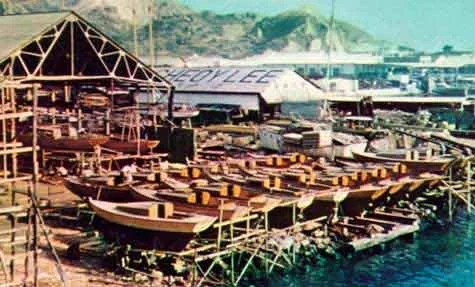

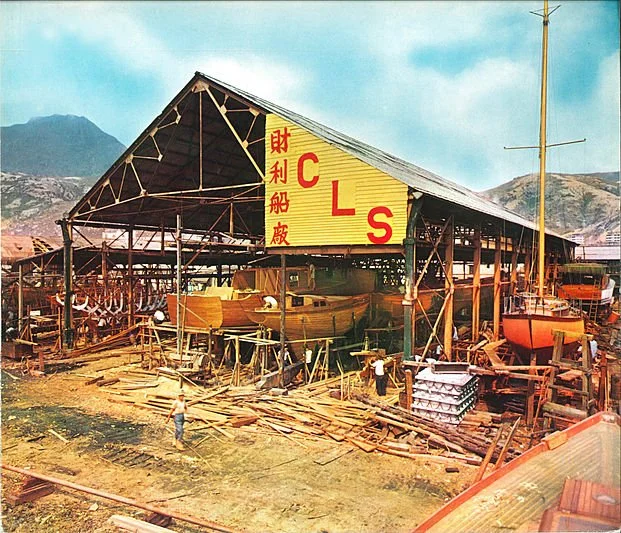

Cheoy Lee Shipyard, Penny’s Bay Hong Kong C1960

Cheoy Lee is a Chinese dynastic business story with generations of the Lo family running a shipyard since the late 19C. Through 150 years, they have survived world wars, military invasions, forced relocation and requisition of machinery and materials and developments in technology. Currently eight brothers of the 4th generation run all departments of the operation specialising in ferries, working harbour boats, tugs and luxury super yachts. This suggests that another Chinese dynastic tradition of polygamy might still have been practiced in Hong Kong after the war. The modern face of Cheoy Lee is Hans Lo, a 5th generation shipbuilder delivering glamorous yachts to Asian dot.com Dragons and tugs to Twiggy Forrest’s FMG in Port Hedland to tow the giant bulk iron ore carriers.

Hans Lo of Cheoy Lee. Photo CL Yachts

Cheoy Lee Rototug FMG SAWFISH on its way to Port Headland WA

The family business started in 1870 building wooden boats and running a repair yard at Po Tung Point, Shanghai. The yard was moved to Penny’s Bay Hong Kong in 1936 after the Japanese invasion of China. Following WW2, Cheoy Lee started to specialise in large scale production of powered wooden trawlers, cargo vessels and teak sailing and motor yachts. By the 1960’s CL was already developing fibreglass hulls and were pioneers of GRP foam sandwich technology. The company had a huge supply of cheap labour in Hong Kong and owned their own teak forests in Burma. They could easily source other tropical timbers used for the keels, stem posts and framing like kayu Ulin (ironwood) and kayu Ipol better known as Merbau from the Ipil Ipil tree. Both were commonly logged in Malaysia and Indonesia.

BURMESE TEAK

Cheoy Lee Burmese teak yachts first became known in America through a 52’ Sparkman & Stephens Bermudan yawl MAH JONG. In 1957 after completion, she sailed the 15,000NM westerly passage from Hong Kong through the Suez Canal to New York “on her own bottom”. In 2014 she was recovered from the British Virgin Islands and restored in 2017 by Gannon & Benjamin in Vineyard Haven MA. See the Seaver Jones stories about the yachts’s background and restoration in “One of a Kind” inside the the G&B link.

MAH JONG post restoration on Vineyard Sound. Photo Tim Wright

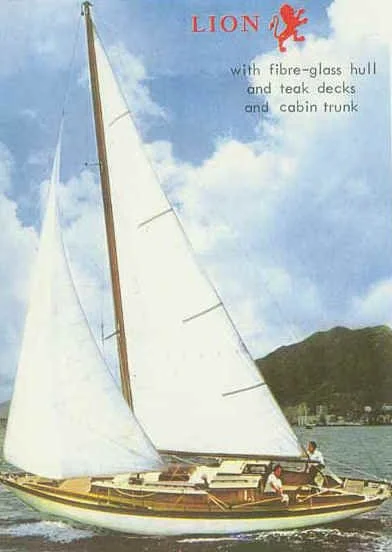

In 1960, an enterprising Californian, David Toombs heard of a 35’ Robb Lion in San Francisco. He discovered it was all teak and built by the little known Cheoy Lee Shipyard in Hong Kong. After an inspection he ordered one for himself. Toombs visited Hong Kong during the build and was so impressed by the shipyard’s capacity and quality, he successfully negotiated for an agency to sell Cheoy Lee yachts in the States. Lion Yachts sold 25 Robb Lion Class teak boats in their first year of business. Toombs worked with Cheoy Lee to make sure the timber and later fibreglass construction methods and auditing would meet Lloyds’ standards to guarantee insurance. CL built at least 70 full teak Robb Lions and another 27 with fibreglass hulls.

By the 1970’s Cheoy Lee were still taking orders but also had their own range of CL Yachts commissioned from leading designers. The popular Clipper and Offshore series were designed by Bill Luders, Ray Richards, Philip Rhodes and John Alden.

Cheoy Lee 1970’s brochure for the 35’ Robb Lion

BILL LUDERS CLIPPERS

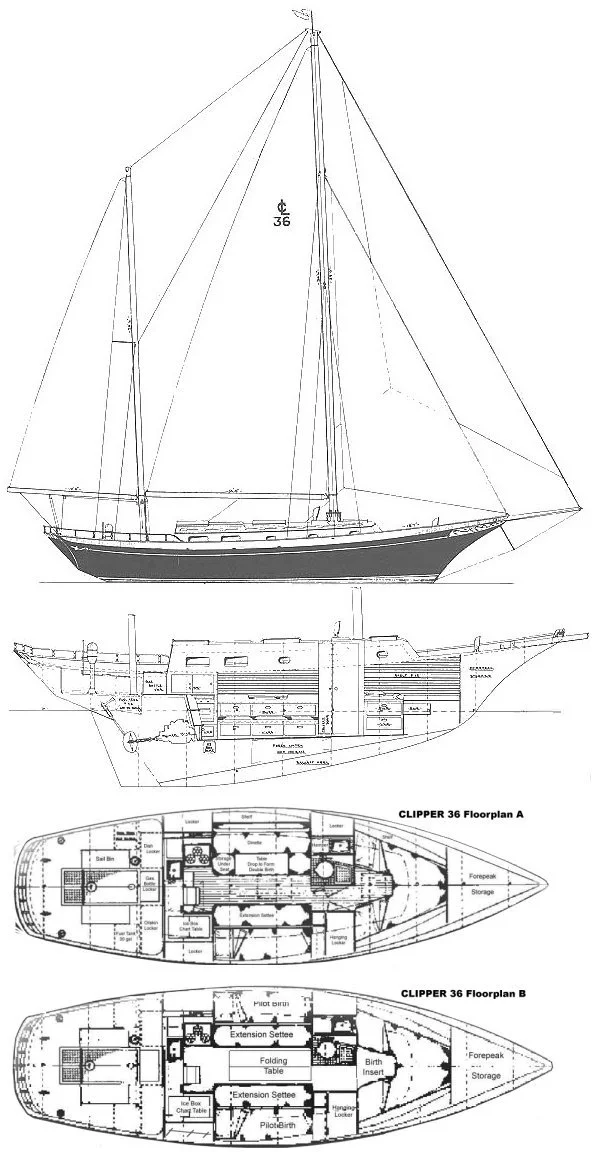

Bill Luders Jnr was a well know naval architect in the USA. He designed training yawls for the Naval Academy at Annapolis and the 12m AMERICAN EAGLE . Cheoy Lee commissioned Luders to design a series of boats known as the Clippers that came in a range of rigs and lengths from 33’ to 48’.

Bill Luders Clipper 36’ for Cheoy Lee

Bill Luders Clipper 36 drawings

RHODES OFFSHORE 40

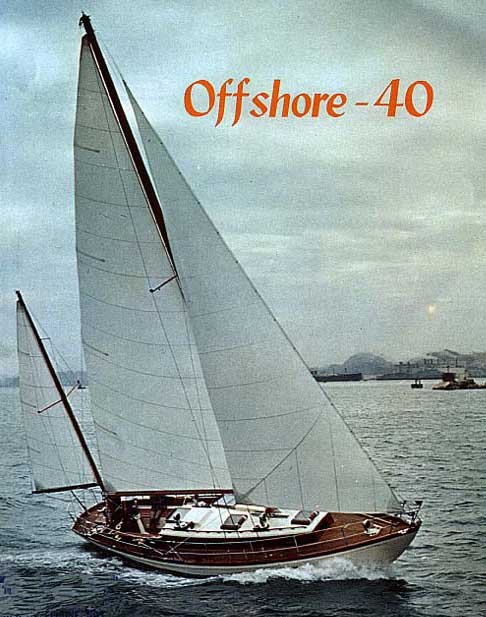

A typical Cheoy Lee story is the American Larkin family living in Asia in the 1960’s. James Larkin was working in Singapore and wanted to race and cruise with other ex-pats. In 1967 he ordered a Cheoy Lee Offshore 40 teak sloop. The boat was a Philip Rhodes design based on his Reliant 41 and could be ordered as a long keel, masthead sloop or yawl. CL built 156 Rhodes Offshores in 12 years from 1964. The Larkin’s MURITAI is still sailing from Sausalito in California.

Cheoy Lee brochure for the Philip Rhodes Offshore 40 C1960’s

Philip Rhodes drawings of the Reliant 41

Rhodes Offshore 40 MURITAI at Cheoy Lee Shipyards 1967. Photo Larkin Family

SEA MAGAZINE 1972

Sea Magazine is still published and uses the tag line “Voice of Pacific Coast Boating since 1908”.

We know better now and can be apologists for exploitation of tropical rainforest timbers, cheap Asian labour and racial stereotyping from the old days. However many of these issues remain today only better disguised by corporate media; “We take seriously our responsibility to ….” etc. In 1972 the reality was on full display in a clunky advertising pitch by Cheoy Lee’s American agents.

When knowledgeable sailors come aboard one of our Cheoy Lee yachts for the first time, they are invariably amazed at the lavish use of Burma teak, the unsparing attention to detail and the overall craftsmanship throughout. But they are even more amazed when they ask the price, and find it to be unbelievably lower than expected. Of course, there is really no inscrutable mystery behind our prices. Just some highly scrutable Orientals.

The Cheoy Lee 1500-man shipyard is located on the bustling Hong Kong waterfront, where it is possible to cut many costs in the construction of fine sailing yachts, without cutting corners with quality. The truth is, no one could sell these yachts at these prices if they were built domestically. The man-hours on a Cheoy Lee yacht are ten times greater than those spent on comparably-priced American Boats. And while the cost of Burma teak is highly reasonable to us, it would be highly unreasonable by the time it was shipped to the States for use on domestic boats.

Cheoy Lee passes these savings on to discriminating sailors in a truly extensive line of fine sailing yachts, all of moulded fiberglass and built exactingly to Lloyds 100A1 specifications. The standard models of all Cheoy Lee yachts are loaded with unexpected features that spell the true difference between a "boat" and a "yacht". Natural Burma teak needs little maintenance and is for all practical purposes immune to decay and worms. Teak neither swells not shrinks to any appreciable degree and owners should enjoy the teak overlays and joiner work which requires very little care.

Other features are hollow Sitka spruce spars, Formica galleys, stainless steel or chromed bronze deck hardware, Wilcox Crittenden toilets and deluxe instrument panels. There are many custom features that can be added by Cheoy Lee. If they weren’t built in Hong Kong, we honestly could not afford to sell them at prices you could afford.